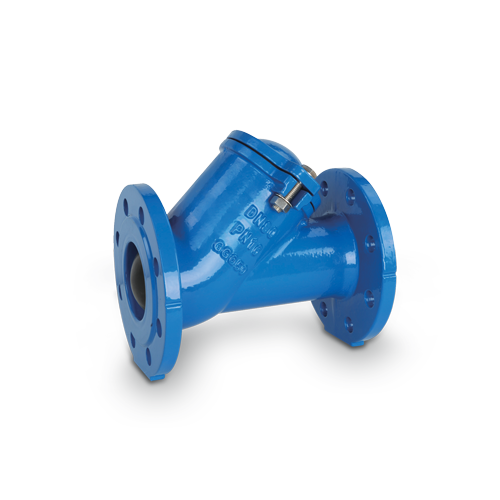

2290 BALL CHECK VALVE

| PRODUCTION STANDARDS | |

| DN40 → DN800 PN 10-16 |

|

| Design | EN 12334 / EN 16767 |

| Connection | Flanged EN 1092-2 / ISO 7005-2 |

| Face to Face | EN 558 Series 48 / DIN 3202 F6 |

| Marking | EN 19 |

| Tests | EN 12266-1 |

| Corrosion Protection |

Electrostatic Bonded Epoxy |

Features

- The ball rotates during operation eliminating the risk of impurities getting stuck on the ball.

- Can be installed in either vertical (upward flow only) or horizontal (cover upright) applications.

- Removable bonnet for cleaning or changing the ball without disassembly out of the pipeline.

- Smooth bore eliminates the risk of deposits at the bottom.

- Designed with focus on easy access to maintenance. By unscrewing a few bolts the bonnet assembly including hinge and ball can be removed from the body, and maintenance can be performed.

- All external surfaces are primed and painted for corrosion resistance.

- Zero stem leakage eliminates media loss and satisfies environmental regulations.

Temperature

- -30 °C, +70 °C

- -10 °C, +80 °C

Scope of Application

- Non-potable water

- Sewage applications

- Wastewater treatment

- Neutral liquids

- Industrial applications

Reviews

There are no reviews yet.